- Time Office:

Opening Hours: Monday - Friday 9 am to 5 pm

- Call Us:

+44 (0) 7533 618966

- Email:

info@loofca.com

manufacturing

- Home

- manufacturing

-

Design: Loofca International’s manufacturing process begins with the design phase. The company’s team of engineers and designers work together to create detailed plans and specifications for each product.

-

Prototype: Once the design is complete, a prototype of the product is created. This allows for testing and refinement of the design before full-scale production begins.

-

Raw Materials: With the design and prototype in place, Loofca International sources all of the raw materials needed to make the product. This may involve working with suppliers or producing materials in-house.

-

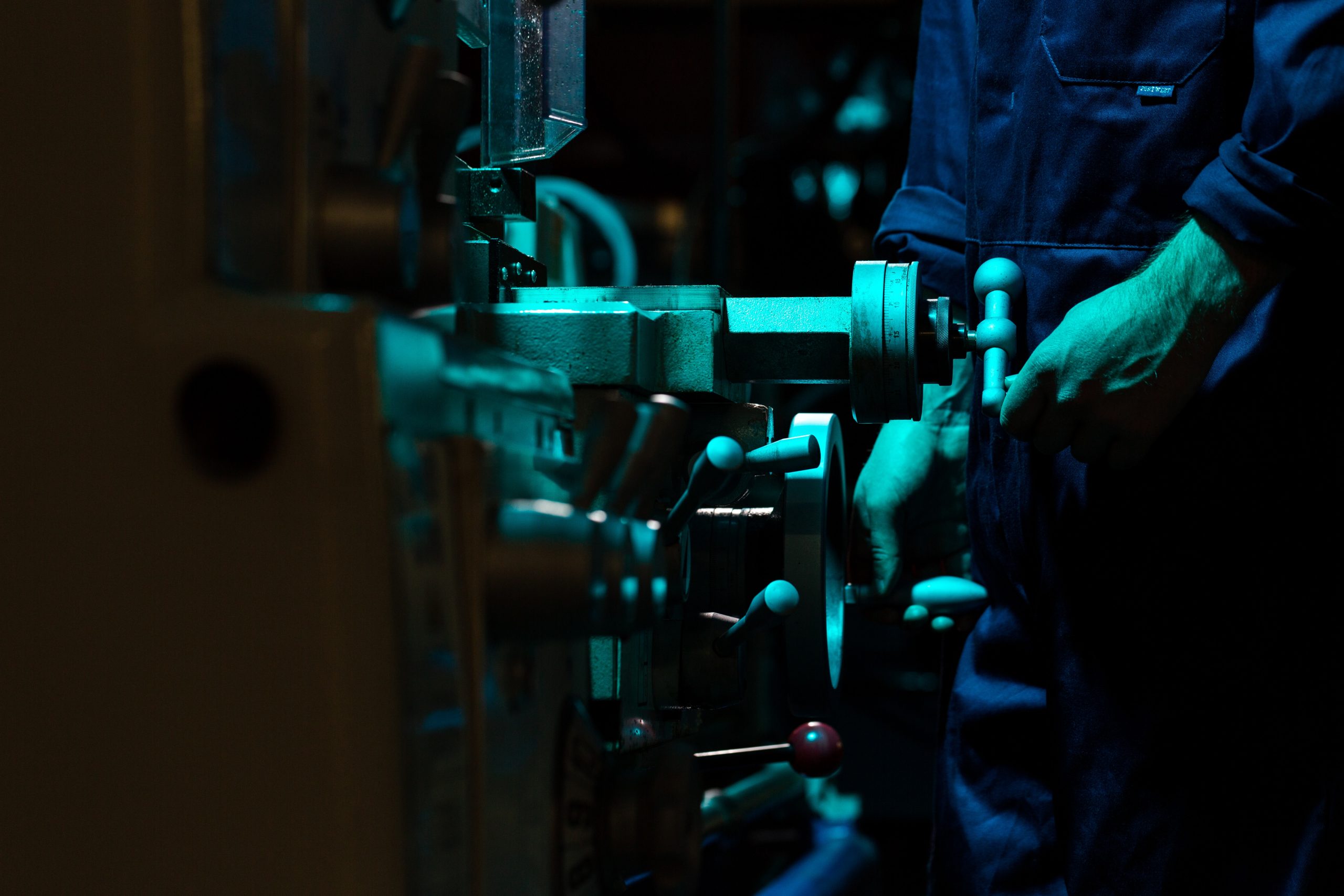

Production: Once all of the raw materials are in place, production can begin. Loofca International’s manufacturing process involves assembling or manufacturing the product according to the design specifications. The company uses state-of-the-art equipment and technology to ensure that each product is made to the highest standards of quality.

-

Quality Control: Throughout the manufacturing process, Loofca International puts in place rigorous quality control measures to ensure that each product meets certain standards of quality. This includes testing each product at various stages of production to identify any defects or issues.

-

Packaging and Shipping: Once the products are complete, they are packaged and shipped to customers or distributors. Loofca International uses high-quality packaging materials to ensure that each product arrives in excellent condition.